帶你了解導(dǎo)軌絲杠的制作過程

來源:http://m.chgdqiyu.com/ 日期:2025-04-19 發(fā)布人:

原材料準(zhǔn)備

raw material preparation

選擇合適的鋼材,如碳素鋼或合金鋼,要求材料具有高強(qiáng)度、良好的耐磨性和耐腐蝕性。根據(jù)產(chǎn)品規(guī)格,將鋼材切割成所需的長(zhǎng)度和尺寸。

Choosing suitable steel, such as high-quality carbon steel or alloy steel, requires the material to have high strength, good wear resistance, and corrosion resistance. Cut the steel into the required length and size according to the product specifications.

鍛造

forge

將切割好的鋼材坯料加熱合適的鍛造溫度范圍,一般在 1000 - 1200℃左右。利用鍛造設(shè)備,如空氣錘、摩擦壓力機(jī)等,對(duì)坯料進(jìn)行多次鐓粗、拔長(zhǎng)等操作,以改善鋼材的內(nèi)部組織,使其更加致密均勻,提高材料的綜合性能,同時(shí)初步形成導(dǎo)軌絲杠的外形。

Heat the cut steel billet to the appropriate forging temperature range, usually around 1000-1200 ℃. Using forging equipment such as air hammers, friction presses, etc., multiple upsetting and stretching operations are carried out on the billet to improve the internal structure of the steel, make it denser and more uniform, enhance the comprehensive performance of the material, and initially form the shape of the guide screw.

機(jī)械加工

machining

粗加工:對(duì)鍛造后的坯料進(jìn)行粗車,加工出絲杠的外圓、螺紋底徑等基本形狀,留一定的加工余量,一般單邊余量在 0.5 - 1mm 左右。同時(shí),對(duì)導(dǎo)軌進(jìn)行粗銑,加工出導(dǎo)軌的大致輪廓和安裝面。

Rough machining: rough machining is performed on the forged billet to produce basic shapes such as the outer circle of the lead screw and the bottom diameter of the thread, leaving a certain amount of machining allowance. Generally, the unilateral allowance is around 0.5-1mm. At the same time, rough milling is performed on the guide rail to produce the approximate outline and installation surface of the guide rail.

半精加工:進(jìn)行半精車,進(jìn)一步提高絲杠外圓和螺紋的加工精度,將外圓尺寸精度控制在 ±0.05mm 以內(nèi),螺紋中徑精度控制在 ±0.02mm 以內(nèi)。對(duì)導(dǎo)軌進(jìn)行半精銑和磨削,使導(dǎo)軌的平面度達(dá)到 0.05mm/m 以內(nèi),表面粗糙度達(dá)到 Ra1.6 - 3.2μm。

Semi precision machining: Perform semi precision machining to further improve the machining accuracy of the outer circle and thread of the screw, controlling the dimensional accuracy of the outer circle within ± 0.05mm and the pitch diameter accuracy of the thread within ± 0.02mm. Perform semi precision milling and grinding on the guide rail to achieve a flatness of within 0.05mm/m and a surface roughness of Ra1.6-3.2 μ m.

精加工:采用高精度的車床和磨床對(duì)絲杠進(jìn)行精車和精磨,將絲杠的外圓尺寸精度控制在 ±0.01mm 以內(nèi),螺紋中徑精度控制在 ±0.005mm 以內(nèi),表面粗糙度達(dá)到 Ra0.4 - 0.8μm。對(duì)導(dǎo)軌進(jìn)行精磨和研磨,使導(dǎo)軌的平面度達(dá)到 0.02mm/m 以內(nèi),直線度達(dá)到 0.05mm/m 以內(nèi),表面粗糙度達(dá)到 Ra0.2 - 0.4μm。

Precision machining: high-precision lathes and grinders are used to perform precision machining and grinding on the lead screw, controlling the outer diameter accuracy of the lead screw within ± 0.01mm, the thread diameter accuracy within ± 0.005mm, and the surface roughness to Ra0.4-0.8 μ m. Fine grind and grind the guide rail to achieve a flatness of within 0.02mm/m, a straightness of within 0.05mm/m, and a surface roughness of Ra0.2-0.4 μ m.

熱處理

heat treatment

淬火:對(duì)絲杠和導(dǎo)軌進(jìn)行淬火處理,將其加熱臨界溫度以上,保溫一定時(shí)間后迅速冷卻,使鋼材獲得馬氏體組織,提高其硬度和耐磨性。一般淬火溫度在 820 - 860℃之間,冷卻介質(zhì)根據(jù)材料和產(chǎn)品要求選擇,如水、油或?qū)S么慊鹨骸4慊鸷螅z杠和導(dǎo)軌的硬度一般可達(dá) HRC58 - 62。

Quenching: Quenching treatment is carried out on the lead screw and guide rail, heating them above the critical temperature, holding them for a certain period of time, and then rapidly cooling them to obtain martensitic structure in the steel, improving its hardness and wear resistance. The general quenching temperature is between 820-860 ℃, and the cooling medium is selected according to the material and product requirements, such as water, oil, or specialized quenching fluid. After quenching, the hardness of the screw and guide rail can generally reach HRC58-62.

回火:淬火后的工件存在較大的內(nèi)應(yīng)力,需要進(jìn)行回火處理。回火溫度通常在 180 - 220℃之間,保溫時(shí)間為 2 - 4 小時(shí),以內(nèi)應(yīng)力,穩(wěn)定組織和尺寸,提高韌性和塑性。

Tempering: The quenched workpiece has significant internal stress and requires tempering treatment. The tempering temperature is usually between 180-220 ℃, and the holding time is 2-4 hours to eliminate internal stress, stabilize the structure and size, and improve toughness and plasticity.

表面處理

Surface Treatment

鍍硬鉻:為了提高絲杠和導(dǎo)軌的耐磨性、耐腐蝕性和表面硬度,通常會(huì)進(jìn)行鍍硬鉻處理。先對(duì)工件進(jìn)行除油、除銹等預(yù)處理,然后將其放入鍍鉻槽中,通過電解作用在表面沉積一層硬鉻層,鍍鉻層厚度一般在 0.02 - 0.05mm 之間。鍍硬鉻后,表面硬度可達(dá) HV900 - 1200,大大提高了工件的使用壽命。

Hard chrome plating: In order to improve the wear resistance, corrosion resistance, and surface hardness of the screw and guide rail, hard chrome plating treatment is usually carried out. Firstly, the workpiece is subjected to pre-treatment such as oil and rust removal, and then placed in a chrome plating tank. A hard chromium layer is deposited on the surface through electrolysis, with a thickness generally between 0.02-0.05mm. After hard chrome plating, the surface hardness can reach HV900-1200, greatly improving the service life of the workpiece.

發(fā)黑處理:對(duì)于一些有外觀要求或需要防銹的導(dǎo)軌絲杠,也可以采用發(fā)黑處理。將工件放入發(fā)黑液中,在一定溫度和時(shí)間條件下,使表面形成一層黑色的氧化膜,既能起到防銹作用,又能改善外觀。發(fā)黑膜厚度一般在 0.01 - 0.02mm 之間。

Blackening treatment: For some guide screws with appearance requirements or rust prevention needs, blackening treatment can also be used. Place the workpiece in black liquor and form a black oxide film on the surface under certain temperature and time conditions, which can not only prevent rust but also improve the appearance. The thickness of the black film is generally between 0.01-0.02mm.

裝配與檢測(cè)

Assembly and Inspection

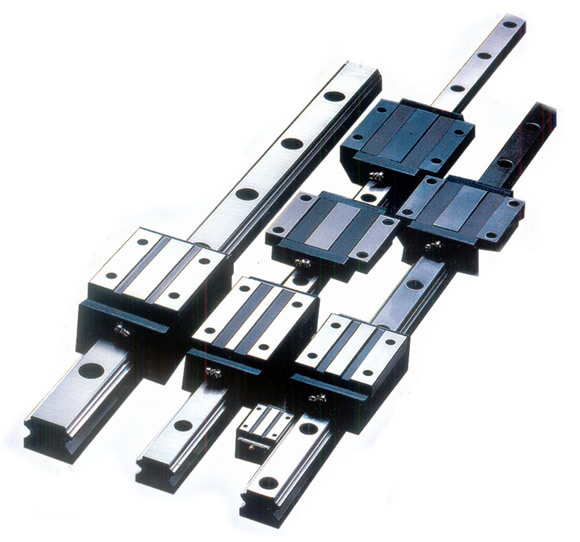

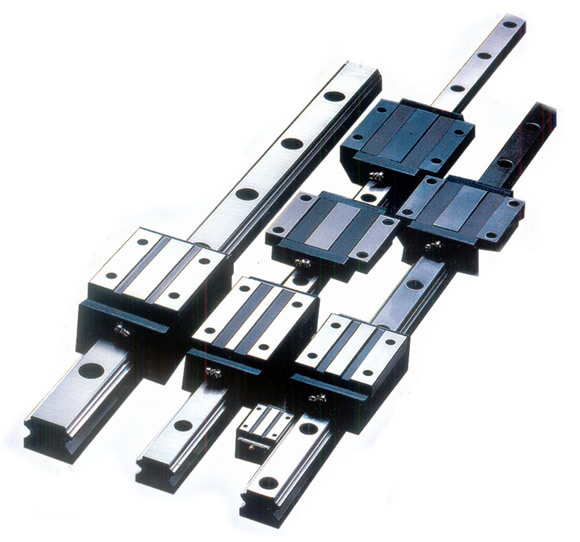

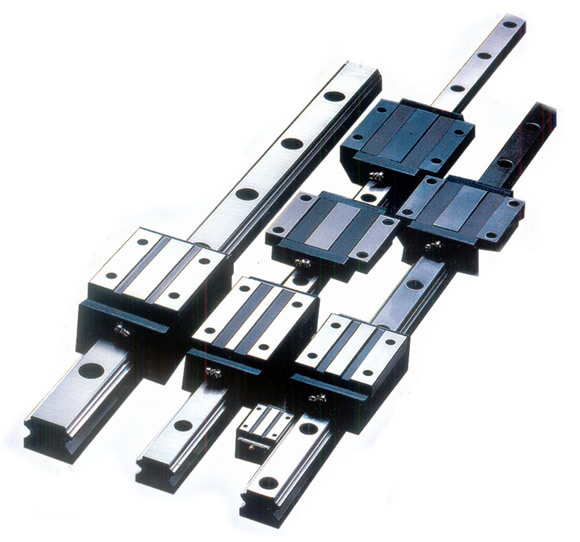

裝配:將加工好的絲杠、螺母、導(dǎo)軌以及其他零部件進(jìn)行裝配。在裝配過程中,要嚴(yán)格控制各部件的配合間隙和安裝精度。例如,絲杠與螺母的配合間隙一般控制在 0.05 - 0.1mm 之間,導(dǎo)軌與滑塊的配合間隙控制在 0.02 - 0.05mm 之間。通過調(diào)整墊片、密封圈等零部件,確保裝配后的導(dǎo)軌絲杠組件具有良好的運(yùn)動(dòng)精度和穩(wěn)定性。

Assembly: Assemble the processed lead screw, nut, guide rail, and other components. During the assembly process, it is necessary to strictly control the fitting clearance and installation accuracy of each component. For example, the clearance between the screw and nut is generally controlled between 0.05-0.1mm, and the clearance between the guide rail and slider is controlled between 0.02-0.05mm. By adjusting components such as gaskets and sealing rings, ensure that the assembled guide screw assembly has good motion accuracy and stability.

檢測(cè):采用三坐標(biāo)測(cè)量?jī)x、激光干涉儀等精密檢測(cè)設(shè)備,對(duì)導(dǎo)軌絲杠的各項(xiàng)精度指標(biāo)進(jìn)行檢測(cè)。包括絲杠的螺距精度、導(dǎo)程精度、跳動(dòng)精度,導(dǎo)軌的平面度、直線度、平行度等。同時(shí),對(duì)裝配后的組件進(jìn)行空載和加載運(yùn)行試驗(yàn),檢測(cè)其運(yùn)動(dòng)平穩(wěn)性、噪聲、溫升等性能指標(biāo),確保產(chǎn)品質(zhì)量符合設(shè)計(jì)要求。

Testing: Precise testing equipment such as coordinate measuring instruments and laser interferometers are used to test the accuracy indicators of the guide screw. Including the pitch accuracy, lead accuracy, and runout accuracy of the screw, as well as the flatness, straightness, and parallelism of the guide rail. At the same time, no-load and load operation tests are conducted on the assembled components to detect their performance indicators such as motion stability, noise, and temperature rise, ensuring that the product quality meets the design requirements.

本文由導(dǎo)軌絲杠友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://m.chgdqiyu.com我們將會(huì)對(duì)您提出的疑問進(jìn)行詳細(xì)的解答,歡迎您登錄網(wǎng)站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 上一篇:導(dǎo)軌絲杠有什么優(yōu)勢(shì)?

- 下一篇:

帶你了解導(dǎo)軌絲杠的制...<>

帶你了解導(dǎo)軌絲杠的制...<> 導(dǎo)軌絲杠有什么優(yōu)勢(shì)?<>

導(dǎo)軌絲杠有什么優(yōu)勢(shì)?<> 絲杠制作復(fù)雜嗎?<>

絲杠制作復(fù)雜嗎?<> 導(dǎo)軌絲杠的日常維護(hù):...<>

導(dǎo)軌絲杠的日常維護(hù):...<> 導(dǎo)軌、絲軌、滑塊安裝<>

導(dǎo)軌、絲軌、滑塊安裝<>