新聞中心

滾珠絲桿的使用技巧你知道是什么嗎?

來源:http://m.chgdqiyu.com/ 日期:2019-01-15 發布人:

運用滾珠絲桿時進行杰出的潤滑是非常必要的,假設沒有充沛的潤滑,作業時鋼珠與翻滾面之間的沖突會添加,并有或許成為壽命縮短的主要原因。

Excellent lubrication of ball screw is very necessary. If there is no sufficient lubrication, the conflict between ball and roll surface will be added during operation, and may be the main reason for shortening service life.

滾珠絲桿的潤滑可選潤滑脂或潤滑油方法,而潤滑方法大致分為手動潤滑與主動強制潤滑兩種,可按照系統的作業速度,運用環境等需求做合適的選擇。

Ball screw can be lubricated by grease or lubricating oil. The lubrication method can be roughly divided into manual lubrication and active forced lubrication. According to the operating speed of the system, suitable selection can be made according to the requirements of the environment.

潤滑脂的給脂頻率依據運用條件與環境而有所不同,一般現象建議每作業100KM的間隔彌補潤滑脂一次,油潤滑方法建議選用粘度為30~150cst的潤滑油。

The frequency of grease feeding varies according to the operating conditions and environment. It is suggested that the grease should be compensated once every 100 KM interval, and the grease with a viscosity of 30-150 CST should be selected for oil lubrication.

滾珠絲桿絲桿保養方法

Maintenance Method of Ball Screw Screw

絲桿所運用的潤滑劑,潤滑脂是運用鋰皂基尼系之潤滑油,其粘度30~40cst(40℃)滑油運用ISO等級32~100。

The lubricant used in the screw rod is a lithium soap-based lubricant with a viscosity of 30-40 CST (40 C) and ISO grade of 32-100.

選擇依據:

Selection basis:

1.低溫用處時:運用基油黏度低的潤滑劑。

1. Low temperature use: use lubricant with low viscosity of base oil.

2.高溫,高負荷或搖擺,低速用處時:運用基油黏度高的潤滑劑。

2. High temperature, high load or rocking, low speed use: use base oil lubricant with high viscosity.

設備在長期作業后許多零件溫度都會上升,這是會影響設備的作業效率。而高精準的設備影響更大,是會損壞精準度。滾珠絲桿是許多設備上都會運用的零件,作業時間久了,溫度就會上升,這樣就會讓精準度下降,這就需要做降溫處理。那都有哪些降溫處理方法?

After long-term operation, the temperature of many parts will rise, which will affect the operation efficiency of the equipment. High-precision equipment has a greater impact, which will damage the accuracy. Ball screw is a part that can be used in many equipments. If the working time is long, the temperature will rise, which will reduce the accuracy, which requires cooling treatment. What are the cooling methods?

1、在滿足產品需求的前提下,盡或許減小滾珠絲桿和軸承座的預緊量;

1. On the premise of meeting the product requirements, reduce the preload of ball screw and bearing seat as much as possible.

2、盡或許選取大的導程,以下降滾珠絲桿的轉速;

2. Choose a large lead whenever possible to reduce the speed of the ball screw.

3、選擇適合的潤滑劑很重要;

3. It is important to choose suitable lubricants.

4、如有條件,運用潤滑油或涼氣對絲桿軸進行強制冷卻。

4. Forced cooling of the screw shaft with lubricating oil or cooling gas if necessary.

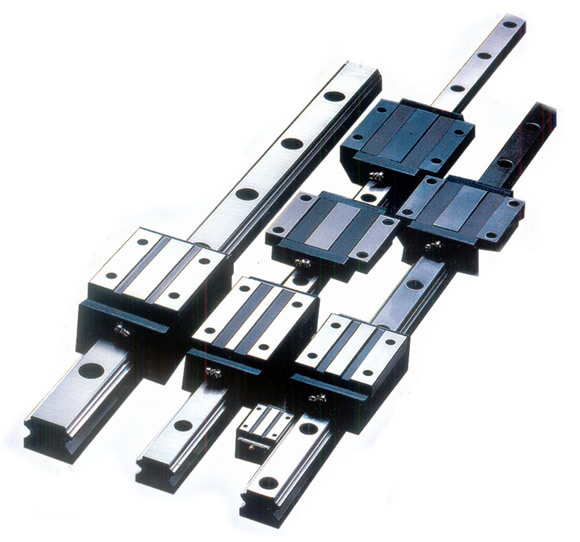

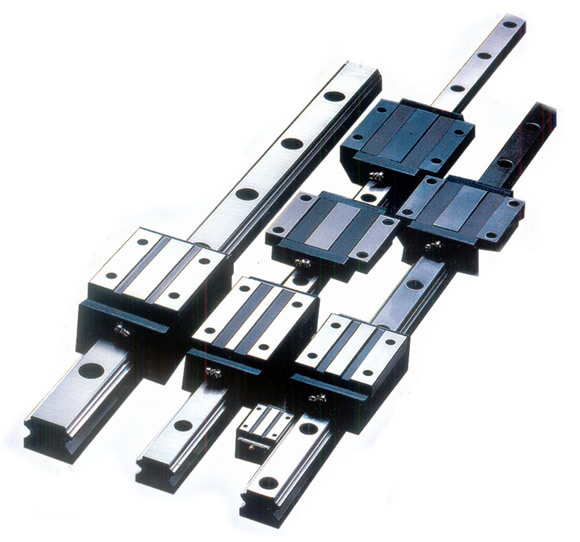

- 上一篇:淺談直線導軌的發展前景!

- 下一篇:怎么樣可以提高滾珠絲桿的性能?

帶你了解導軌絲杠的制...<>

帶你了解導軌絲杠的制...<> 導軌絲杠有什么優勢?<>

導軌絲杠有什么優勢?<> 絲杠制作復雜嗎?<>

絲杠制作復雜嗎?<> 導軌絲杠的日常維護:...<>

導軌絲杠的日常維護:...<> 導軌、絲軌、滑塊安裝<>

導軌、絲軌、滑塊安裝<>

相關: